5 important things you need to know when determining filter press capacity

If you are looking to learn the most important points in determining filter press capacity, join us in this article

VisitCount 76

filter press capacity

The materials that are filtered and pressed play a significant role in determining the capacity of the filter press. Generally, the filter press capacity depends on both the liquids and solids fed into the machine. It is worth noting that the capacity of the filter press in water and wastewater treatment is easily calculated because only a small number of filter press plates are used.

However, when filtering materials like biological sludge, calculating the filter press capacity, which depends on cake thickness and internal length, becomes difficult because of the number of filter press plates used.

If you need more accurate calculations for designing, manufacturing, or purchasing a filter press, you can reach out to the experts at Danafon Company, The capacity of a filter press depends on several factors, which we will explore in this article.

Among the important factors that determine the capacity of a filter press are the following

- Size of filter press plates

- Number of filter press plates

- Volume of wastewater (including solids and liquids)

- Type of wastewater being filtered

- Solid content in the wastewater

Below, we will discuss each of the factors listed above separately

1.The size and dimensions of the filter press plates

- Number of cycles performed per day

- Number of cycles performed per hour

- Input flow rate of the device

- pH calculation of the effluent

- Available space for device installation

- Calculation of mud production in the relevant factory

- Devices used in each production line. For example, in stone cutting factories, the amount of wastewater produced during peak cutting and sawing times varies, which affects the production rate

- Produced during peak cutting and sawing periods, which causes fluctuations in the production rate

2.The number of filter press plates

The second important factor in determining and calculating the capacity of a filter press is the number of filter press plates. In fact, all the factors mentioned above for determining the dimensions of the filter press plates also influence the number of plates used, click the link below to learn more about filter press plates.

3.The amount of available wastewater

Generally, the amount of effluent is a key factor in designing filter presses with varying capacities. In fact, it is crucial to consider the amount of materials primarily subjected to filtration. The greater the amount of effluent entering the device, the higher the required capacity of the device. It is important to note that the amount of effluent includes both solids and liquids

For instance, if the solid content in the wastewater is high, additional plates are required for filtration. Since increasing the number of plates directly affects the device's dimensions, a larger filter press must be built to accommodate this.

4.Type of effluent being filtered

In the wastewater treatment process, which is fully explained in a separate article, there is a stage where flocculant powder is mixed with water in the preparation unit and then injected into the wastewater in the clarifier tank. The settling rate of the solids in the clarifier tank also depends on whether the suspended particles in the water are hydrophilic (water-attracting) or hydrophobic (water-repelling). If you wish to become familiar with the complete wastewater treatment process, you can refer to the wastewater treatment article.

In fact, it can be said that the type of effluent creates two different conditions for us:

- Effluent with hydrophilic particles

- Effluent with hydrophobic particles

Effluent with hydrophilic particles

If the wastewater has hydrophilic properties, such as wastewater containing sand or fine particles, the filtration cycle time will be significantly longer compared to hydrophobic wastewater. This is because the separation of solid particles from the liquid in hydrophilic wastewater is more difficult, which naturally increases the time required to complete a filtration cycle. Consequently, this factor has a direct impact on filter press calculations.

When the required time for a cycle is longer, special attention must be paid to the design and calculation of the system’s capacity, For instance, in the case of hydrophilic wastewater, it may be necessary to increase the filter press capacity.

This can be achieved either by enlarging the size of the plates or by using a greater number of different types of filter press plates that are suitable for the slurry or wastewater in question, Selecting the correct and appropriate filter press plates based on the type of wastewater plays a critical role in efficiency, filtration speed, and operational cost reduction.

In fact, understanding the characteristics of the wastewater and considering the differences in filtration cycle times are key to designing an optimized system and accurately determining the filter press capacity, ensuring that even difficult-to-separate wastewater can be processed efficiently without compromising overall filtration performance.

Effluent with hydrophobic particles

If the effluent is hydrophobic, the separation of solids and liquids within the solution occurs much more easily. For example, if a filter press cycle takes about one hour for a hydrophilic effluent, the same process may take only five minutes for a hydrophobic one. This significant time difference plays an important role in determining the appropriate capacity of the filter press.

5.The amount of solid content in the effluent

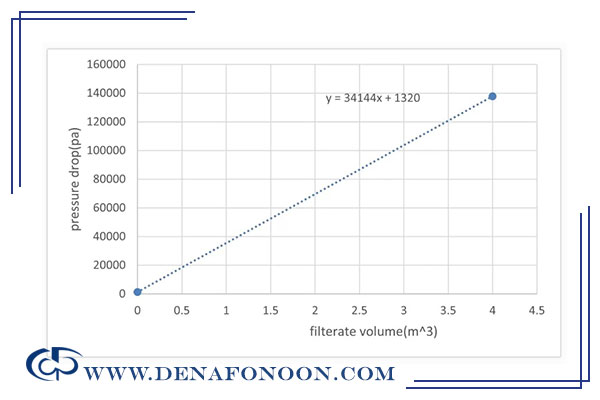

The higher the concentration of solid particles in the wastewater, the longer the filtration cycle will take. This factor directly affects the determination of the filter press capacity, since a larger volume of solids requires a machine with greater capacity, In fact there is a chain-like relationship between:

- The amount of solid particles

- The dewatering time

- The filter press capacity

Each of these elements influences the others. In other words, when wastewater contains a high contamination load and a higher concentration of solids, a filter press with a larger capacity ensures optimal performance. Conversely, in cases where the wastewater volume is lower, selecting a machine with a suitable capacity not only reduces operating costs but also improves overall system efficiency.

Therefore, accurate filter press calculations and proper determination of the filter press capacity, based on wastewater characteristics and solid content, are among the most critical factors in the design and operation of treatment systems.

If you require more precise calculations, you can contact the experts at Denafonoon Company, Our team is ready to provide you with helpful and professional guidance.