What is a Thickener?

Explore what a thickener is, its types, and applications in mineral processing and industrial wastewater treatment

VisitCount 210

What is a Thickener?

A thickener tank is an essential unit designed and manufactured for the treatment of wastewater generated in mining industries, such as:

- Stone quarries

- Copper mines

- Iron ore mines

- Aluminum mines

- Sand and gravel mines

In sand and gravel plants, a large amount of water is required for washing the produced materials. The thickener tank is the most efficient solution for these mines to optimize water usage during product washing operations.

It serves as a large-scale reservoir for water recovery and cost reduction in mining activities. Moreover, by employing a thickener tank, there is no need for traditional wastewater treatment methods.

Thickeners are usually installed at the final stage of the production process, where they recover over 95% of the process water and return it to the production line. Consequently, the drawbacks of traditional wastewater treatment systems are completely eliminated in this method.

Types of Thickeners:

1. Conventional Thickener:

The conventional thickener is the most commonly used type and can be classified into three main categories:

- Bridge-supported thickener

- Column-supported thickener

- Rail-mounted thickener

Bridge-Supported Thickener

Column-Supported Thickener

The column-supported thickener has the following characteristics:

- It includes a fixed central column that supports the drive mechanism and rake arms.

- This design is generally recommended for tank diameters exceeding 40 meters.

- In this model, a bridge is used to provide access for maintenance and to support the feed well and launder system.

2. Deep Cone Thickener

The deep cone thickener is characterized by the following features:

- It has a greater height compared to conventional thickeners.

- It consumes more flocculant.

- The upward flow velocity of the clarified liquid is relatively high.

- The underflow solids concentration is greater.

- It requires less installation area.

- However, it has more complex operational control compared to standard designs.

3. Multi-Stage Thickener

The multi-stage thickener system possesses the following features:

- The thickening units are stacked vertically, one above the other.

- Each stage’s rake mechanism is mounted on a common central shaft.

- All stages share a single underflow discharge outlet.

Advantages of Multi-Stage Thickeners:

- Reduced installation footprint

- Lower construction material requirements

- Lower energy consumption when heating is required

Disadvantages:

- Lower underflow solids concentration

- More complex operational control

4. Lamella Thickener (Inclined Plate Clarifier)

Key features of the lamella thickener include:

- Utilization of inclined plates to increase the overall effective settling area within the clarification zone.

- The effective settling area equals the projected horizontal area of each plate multiplied by the number of plates.

- No rake mechanism is used.

- Smaller installation footprint compared to conventional thickeners.

Applications of Thickeners

- In general, during the production and processing of mineral materials such as copper, gold, aluminum, iron, and stone, a significant amount of water is consumed.

- Similarly, in the sand production industry, which involves aggregate washing operations, large volumes of process water are required.

- Thickener tanks are utilized to recover and recycle this water, thereby reducing overall water consumption and operational costs.

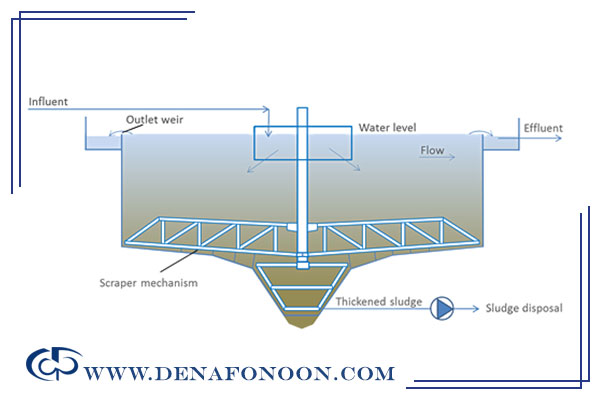

Working Principle of a Thickener

When solid particles settle in a suspension, two distinct phases are formed — a clarified liquid layer and a concentrated slurry (pulp) at the bottom.

The settling velocity of the particles depends primarily on their size and density. Smaller or lighter particles tend to settle more slowly.

Therefore, in many cases, the sedimentation process must be enhanced using one or more of the following methods:

- Applying centrifugal force to accelerate particle separation.

- Adjusting environmental conditions to promote particle aggregation and increase settling velocity.

- Adding flocculant powder, which binds the fine solid particles into larger flocs, thereby increasing their settling rate. This process is known as flocculation.

Among the available methods for solid-liquid separation, thickening is considered one of the most cost-effective and high-capacity options.

Sedimentation occurs inside tanks known as Thickeners, where the clarified water accumulates in the upper section, and the concentrated sludge (underflow) is collected at the bottom.

Thickeners can operate in either continuous or batch mode.

In continuous operation, the concentrated slurry is continuously withdrawn from the bottom, while clarified water overflows from the top.

Features of a Continuous Thickener

- Cylindrical sedimentation basin

- Tank diameter ranges from 2 to 200 meters, depending on the required capacity

- Tank depth typically between 1 and 7 meters

- The feed pulp enters through a central feed well, located at the tank’s center

- The feed pipe extends slightly below the pulp surface to minimize turbulence

- Clarified water overflows from the top section

- The underflow slurry is discharged through the outlet at the bottom

- A gentle slope at the tank base facilitates sludge discharge

- A set of rotating rake arms at the bottom continuously move the settled solids toward the central discharge cone

Design and Construction of a Thickener

One of the most critical considerations in the design and construction of a thickener is determining its appropriate size, which depends on the specific application and process requirements.

Sizing a thickener requires defining two main parameters:

- The surface area needed to prevent the formation of a critical solids concentration zone.

- The bed depth required to achieve the desired underflow solids concentration.

A well-known method for determining thickener area, particularly for non-flocculated pulps, is the Coe–Clevenger method.

This method utilizes zone-settling or compression-settling models to calculate the required thickening area, based on the principle that the settling rate of the pulp is a function of solids concentration only.

The steps of the Coe–Clevenger method are as follows:

- Measure the initial settling rate using several pulp samples with different concentrations.

- Calculate the required area for each solids concentration.

- Determine the maximum area per unit weight of solids processed per day.

Thickener Manufacturers

One of the notable manufacturers of thickener tanks in Iran is Denafonoon Company, which is also among the pioneers in the production of mineral processing machinery and filter press, These thickeners are primarily used in mining applications, where large-scale wastewater treatment and high-volume water recovery are required.

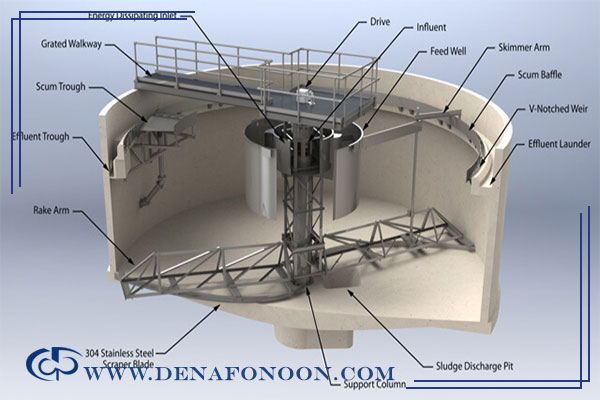

Components of a Thickener

The structure and components of a thickener depend largely on its construction material.

Thickeners are generally manufactured as metallic or concrete tanks, each having specific design features.

Metal Thickener Tank

The main components of a metal thickener include:

- Tank shell (main body made of steel plates)

- Support structure

- Feed launder

- Feed well

- Rake mechanism

- Agitator

- Gearbox and drive unit

- Bridge structure

Concrete Thickener Tank

The components of a concrete thickener are similar to those of a metal unit, with the main difference being the tank body material:

- Reinforced concrete tank (main body)

- Support structure

- Feed launder

- Feed well

- Rake mechanism

- Agitator

- Gearbox and drive unit

- Bridge structure

As shown above, both designs share similar mechanical features; the primary distinction lies in the tank material, which is selected based on operational requirements, installation site, and client preference.

Difference Between a Thickener and a Clarifier

One of the key differences between a thickener and a clarifier lies in their water storage capacity.

A thickener is designed to retain a larger volume of water, making it ideal for mining and mineral processing operations where high water recovery rates are essential.

Other major differences include:

1. Difference in Application

Thickener Applications:

- Water recovery and recycling

- Reduction of tailings volume

- Mineral processing and concentration plants

- Handling slurries with high solids content and large flow rates

- Generally subject to higher mechanical wear than clarifiers

Clarifier Applications:

- Industrial and municipal wastewater treatment

- Clarification and removal of suspended solids

- Improvement of effluent water quality

- Lower mechanical wear compared to thickeners

2. Difference in Design

A thickener typically features a large diameter and shallow depth, while a clarifier usually has a longer tank with a conical bottom section for sediment collection and sludge removal.

3. Difference in Operation

In a thickener, sedimentation occurs slowly with the assistance of rotating rake arms that move settled solids toward the discharge cone.

Chemical additives such as flocculants may be used to accelerate particle settling.

In contrast, clarifiers perform sedimentation at a faster rate, often aided by coagulants and flocculants, but they are generally designed for lower solids concentrations.

4. Difference in Industrial Use

Due to their ability to handle high-solids and high-flow slurries, thickeners are primarily used in:

- Ore beneficiation plants

- Metal extraction processes

- Tailings management systems

Whereas clarifiers are commonly used in:

- Municipal water and wastewater treatment plants

- Food and beverage industries

- Chemical industries

- Stone processing and polishing units

Thickener Pricing

The price of a thickener tank depends on several key factors, including:

- Tank size and capacity

- Construction material (steel or concrete)

- Type and quality of materials used in fabrication

- Mechanical and automation specifications