The Importance of Starch Wastewater Treatment

The Importance of Starch Wastewater Treatment

VisitCount 113

The Importance of Starch Wastewater Treatment:

Before discussing the starch filter press and its role in wastewater purification, it is essential to understand the overall importance of wastewater treatment in the starch industry, Starch is one of the most widely used raw materials in various sectors such as food production, pharmaceuticals, paper manufacturing, and textiles.

Industries involved in starch and flour production consume a large volume of water throughout different stages of processing. As a result, these operations generate significant amounts of industrial effluent, which typically contains:

- Organic compounds

- Chemical substances

- Dissolved organic carbon

- Nutrients such as nitrogen and phosphorus

If these effluents are discharged into the environment without proper treatment, they can cause serious environmental issues, including:

- Contamination of soil and water resources

- Ecological imbalance

- Harm to aquatic and terrestrial organisms

- Risks to human health

Therefore, implementing efficient and sustainable wastewater treatment systems in starch production is vital. Moreover, the technologies used must comply with eco-friendly and hygienic standards, ensuring both environmental protection and reuse of treated water within the process.

Challenges in Treating Starch Wastewater

Due to the complex and multi-stage nature of starch production, this industry generates wastewater with high organic load and unique chemical composition, Some of the main challenges in starch wastewater treatment include:

1. High Concentration of Organic Matter:

Starch production wastewater contains large amounts of carbon-based compounds. Without proper treatment, it can significantly increase Biochemical Oxygen Demand (BOD) and Chemical Oxygen Demand (COD) in the receiving environment.

2. Presence of Specific Chemical Compounds:

Certain stages of production involve additives or chemical reactions that produce substances requiring specialized and multi-stage treatment methods for effective removal.

3. Large Volume of Wastewater:

Because water is used extensively in washing, separation, and cooling steps, the total volume of wastewater generated is quite high, To handle this efficiently, starch filter presses are employed one of the most reliable solid-liquid separation technologies available today. These systems must deliver high capacity, operational stability, and optimal performance to meet industrial demands.

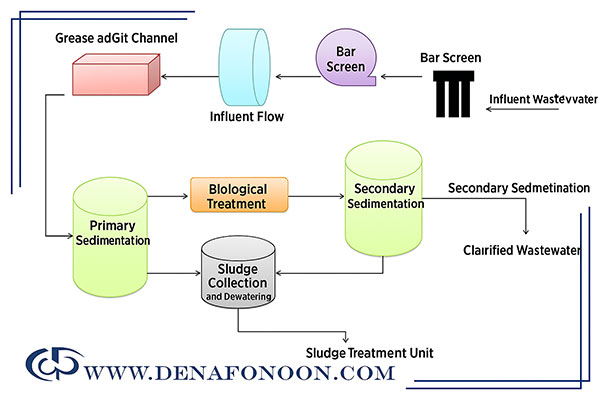

Main Stages of Starch Wastewater Treatment

The following are the steps of starch wastewater treatment, examined in order.

1. Preparation of Starch Slurry

The starch slurry is a mixture of water and solid particles obtained from milling raw materials such as corn or wheat. It typically contains starch, fibers, proteins, and impurities that have not yet been separated.

This step forms the basis of all subsequent separation processes and includes:

Milling and Grinding: Raw materials are soaked to soften them before grinding.

Water Mixing: The ground material is mixed with clean, preferably warm water (low hardness, chlorine-free). Enzymes may be added to aid the process.

Temperature and pH Adjustment: These parameters are controlled to prevent starch degradation and maintain optimal viscosity and enzyme activity.

Screening and Homogenization: Heavy particles are removed through filters, and the slurry is stored temporarily for uniform composition.

2. Feeding the Slurry into the Starch Filter Press

This is one of the most critical stages, directly influencing final starch quality and filter performance, The slurry is pumped into the filter press using a special feed pump, filling the filter chambers, Filtration then occurs, separating the solid cake from the liquid, Once the chambers are full, the filter cake is discharged from between the plates.

3. Types of Filter Presses Used in Starch Wastewater Treatment

Depending on the desired dewatering efficiency and cake dryness, different types of filter presses can be used, including:

- Chamber Filter Press

- Membrane Filter Press

- Automatic Filter Press

- Manual Filter Press

- Open-Type Filter Press

- Closed-Type Filter Press

Benefits of Filter Press in Starch Wastewater Treatment

- Reduced Water Consumption: Up to 80–90% of clean water can be recovered and reused.

- Higher Product Yield: Improved purity and recovery of final starch.

- Significant Reduction of Pollution Load: Proper filtration lowers effluent contamination levels dramatically.

- Lower Energy Consumption: Compared to evaporation or centrifugation systems.

- Durability and Low Maintenance Costs: Long service life and minimal operational expense.

Technical Considerations for Optimization

- Select filter cloths with proper permeability and material for starch particles.

- Adjust filtration pressure and time according to slurry concentration.

- Clean filter plates regularly to prevent clogging and maintain efficiency.

- Use coagulants or flocculants to enhance particle settling and filtration performance.

- Control wastewater temperature to prevent starch gelatinization.

Environmental Considerations

Untreated starch wastewater has high organic loads (BOD/COD), leading to environmental pollution, By employing filter press technology, pollution loads can be reduced by over 70%, and the treated water can be safely reused in production lines, Additionally, the filter cake obtained can be repurposed as animal feed or biofuel, supporting circular economy principles.