filter press in brick manufacturing

filter press in brick manufacturingوExplore the role of the filter press in brick manufacturing, a vital tool for optimizing water usage, improving slurry quality, and enhancing overall production efficiency in the brick industry

VisitCount 49

Applications of Filter Press in Brick Manufacturing

Brick factories, due to the large-scale production of bricks, consume a significant amount of water in each step of the manufacturing process. This leads to a growing need for the implementation of filter press systems in the brick industry. The primary water usage in this process is for preparing the brick slurry.

In this industry, clay is mixed with water to create the slurry used for brick production. Water consumption is high in this phase, and the most effective solution for water recovery and efficient usage in this sector is the use of the brick manufacturing filter press.

The use of a filter press in this industry allows for the water contained in the slurry, which is used to make bricks, to be efficiently managed and reused. It also helps the resulting slurry to be drier. In summary, the benefits of this system include:

- Higher-quality brick production

- Reduced water consumption

- Drier slurry production

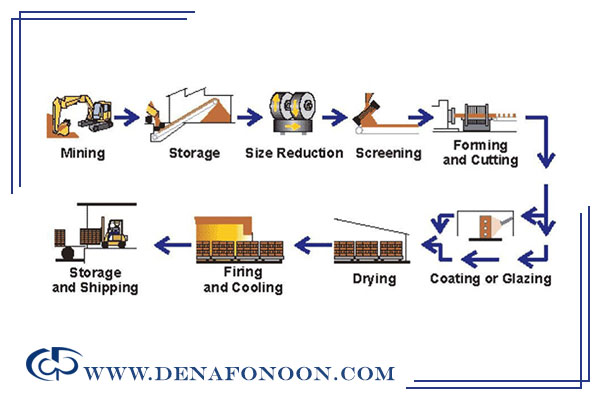

To better understand the application of filter presses in brick manufacturing, let's take a closer look at the brick production process. This will allow us to pinpoint exactly when water is used and where it can be recovered and reused with the help of a filter press.

Brick Production Process

The basic method for making bricks has remained largely unchanged for thousands of years, ever since the first fired bricks were produced. While the methods used in ancient times have been adapted, many are still in use today. Below are the different stages of brick production and the role of the filter press in these stages:

- Stabilizing Clay

- Enrichment

- Mixing and Molding

- Drying

- Firing and Cooling

Let's explore each stage in more detail:

Stabilizing Clay:

The clay used today is more diverse compared to the early days of brick manufacturing. Mining and various milling techniques allow manufacturers to use a broader range of raw materials.

Clay typically consists of varying amounts of silica and alumina, It can be classified into three categories:

- Surface clays: Found near the earth's surface, often in riverbeds, These clays are usually extracted using electric shovels, bulldozers with scraping blades, and dragline operations.

- Clays subjected to high geological pressure: These clays range from shale to disintegrated rock, Shales are mined through blasting and electric shovels.

- Fire clays: Located deeper underground, fire clays have a more consistent chemical composition than surface clays or shales, They are extracted using conventional mining techniques

Enrichment

During the enrichment process, clay is often milled to reduce large stones or clay masses to a usable size before being stored in silos. As excess materials are stored, samples are mixed from various parts of the storage pile.

The materials are then transferred to secondary mills and screens (if needed) to ensure that the particle size is optimized for mixing with water. In some cases, like with soft clays, the clay is directly sent to the mixing area without the need for additional milling or screening.

Mixing and Molding

Water is heavily used in the brick manufacturing process during the mixing and molding stage. At this point, all clays are mixed with water to form a workable product, which heavily depends on the nature and plasticity of the clay. The water is released during the drying and firing processes.

This stage is crucial in demonstrating the importance of filter presses. A large amount of water is consumed in this phase, and without a filter press, much of it is wasted. However, with the use of a filter press, excess water in the slurry can be recovered and reused in the production line.

In the molding and mixing phase, the clay is blended with water to make it plastic. The resulting mixture is then passed through molds, which shape the clay into the desired form, much like toothpaste being extruded from a tube.

Older methods of brick production come with several drawbacks, such as:

- Excessive water usage in the "soft mud" process

- The use of wooden molds to form the desired unit size

- To prevent clay from sticking, the molds are lubricated with sand or oil

- Excess clay is scraped off the top of the molds

- These methods result in bricks with very low plasticity and often lead to the production of "wooden" bricks, sandblasted bricks, or water-blasted bricks.

The dry press method, on the other hand, requires minimal water, and the materials are placed in steel molds and subjected to pressures of up to 10,000 kPa.

Drying

Once the bricks are molded, they must be dried. The drying process involves two stages:

- Sun drying

- Kiln drying with controlled temperature, tension, and humidity

Firing and Cooling

Bricks require a specialized chamber, known as a kiln, to undergo the firing process. The raw materials are placed inside the kiln, where temperatures between 870°C to 1100°C (1600°F to over 2000°F) are applied. During this stage, the bricks are both fired and cooled.

There are two types of kilns used for brick firing:

- Continuous kilns: These kilns have tunnels at the bottom, allowing heat to pass through the mass of bricks, rising toward the top. The walls and the upper sections are insulated with a mixture of sand, clay, and water.

- Periodic kilns: These kilns feature ample air space for the bricks, allowing heat to gradually increase until it reaches the optimal firing temperature. Heat is transferred from one chamber to the next until the bricks are properly fired and gradually cooled before being removed.

Automation

From the time the kiln was developed, brick manufacturers have sought to increase automation in their processes. Today, bricks that have been removed from the kiln are immediately packed into special brick packaging, tied with steel ropes, and transported using mechanical storage equipment.

Filter Press and Brick Manufacturing

The use of filter press machines in the brick industry is now a common practice in many brick-producing countries, including Iran. The introduction of filter press machines has significantly facilitated the process of water recovery, making it quicker and more efficient. With minimal effort, filter presses are able to recover water and reintroduce it into the production cycle, helping conserve valuable water resources.